SIMPLEST WAY INTO THE NEXT GENERATION OF NDT INSPECTION

THE LEADER IN COMPOSITES

Dolphitech is recognised worldwide for high-quality and high-definition ultrasonic Non-destructive testing products, utilising unbeatable matrix imaging technology to inspect and detect damage, degradation, and defects in mission-critical assets across various industries.

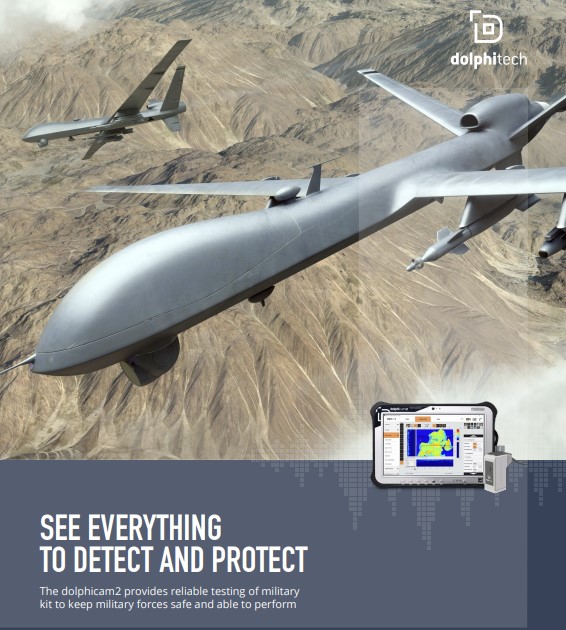

Military vehicle inspection

· Fixed wing and rotary wing inspections for both manned and un-manned aircraft as well as varied ground vehicles;

· Battle field, in-service and maintenance level inspections, all with connectivity for remote expert support;

· Simplified go/no-go software functionality with no latency for instant pass/fail screening;

· Preconfigured settings files for particular assets: reduce set up time and remove operator variability;

· Fully digital records that can be shared with different bases and with OEM;

· Low training requirements for use in the field

What inspection tasks you can fulfil?

- Can be used in manufacturing or in-service;

- Can be used for routine inspection (checking for erosion/corrosion on fuselage);

- Can be used to assess damage – battle or impact;

- Can be used quickly, easily and remotely (subject to connectivity);

- Full digital records from inspection

In composites:

- A wide variety of low velocity and high velocity impact damage, which may cause delaminations and disbonds;

- Low Observable coating thickness and bonding integrity to substrate checks;

- Sandwich structures on control surfaces for disbonds, battle damage and water ingress.

In metals:

- General and pitting corrosion

- Disbonds between similar and dissimilar adhesive joints.